Manufacturing possibilities with the electron beam

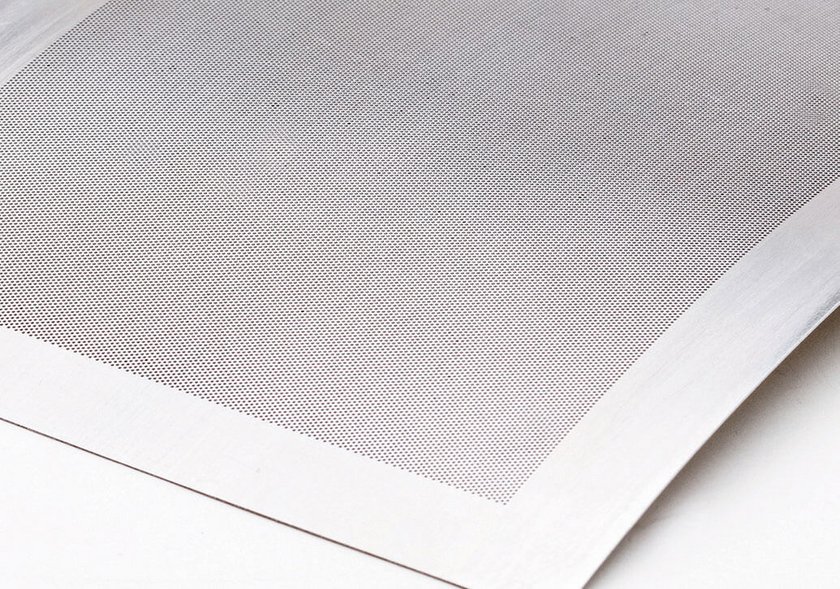

We use an electron beam to manufacture micro-drilled perforated sheets and components. Our technology is able to drill the finest round holes and slots as well as realize conical and cylindrical openings in a fineness range from 60 - 1800 µm. In addition, high numbers of holes and deep holes are also possible.

Electron beam drilled elements are particularly well-suited for production processes in which the smallest holes and slots are required in relatively thick walls (0.3 mm up to 8 mm). The same is also true where high product requirements and demanding process conditions predominate. They are therefore the perfect choice for filter and screen media as well as centrifugal disks.

The perforated sheets can be individually configured: The drilling pattern can be flexibly adapted to specific system and process requirements. With regard to the material, a choice can also be made between all metallic alloys, including titanium and superalloys.

Stainless steel filter and screen media: micro-drilled, durable, easy-to-clean

Whether in the food and beverages, paints and varnishes or pulp and paper production industries: Each application places very different demands on the processing procedure and thus on the filter medium.

With micro-drilled filter and screen media from pro-beam, you benefit from:

- Easy cleaning, even with difficult media thanks to conical holes and the smooth surfaces of the separation elements

- Longer durability than conventional solutions because the sheets are reusable and can resist even mechanical stress

- Finest results due to the smallest holes and slots

Our micro-drilled filter and screen media are versatile and can be used in a wide range of systems.

Micro drilling with the electron beam

When drilling with an electron beam, the high energy density of the electrons melts sheets or cylindrical workpieces at a defined location without affecting the surrounding areas. Micro drilling machines from pro-beam work quickly and precisely, producing up to 3,000 holes per second. The entire drilling process takes place in a vacuum.

Industries

- Food and beverages

- Paints and varnishes

- Pulp and paper

- Recycling

- Insulation industry / glass wool production

- Dies and punches

- More on request

Systems for micro-drilled filter and screen media:

- Vacuum and pressure filters

- Industrial filter and screen systems

- Centrifuges, e.g. screw centrifuges, filter and screen centrifuges

- Fine impact mills with integrated screening

- Separators with continual solid separation

- Self-cleaning and backwashable systems